"Nagmani Lathe" offers wide range of lathe machines of various sizes, specifications and features depending on the Customer requirement. our Lathe Machines are extensively used in various fields like automobiles/ Rubber Roller / Sugar mill / Paper mill / heavy engineering and over & above all general engineerint maintenance workshop

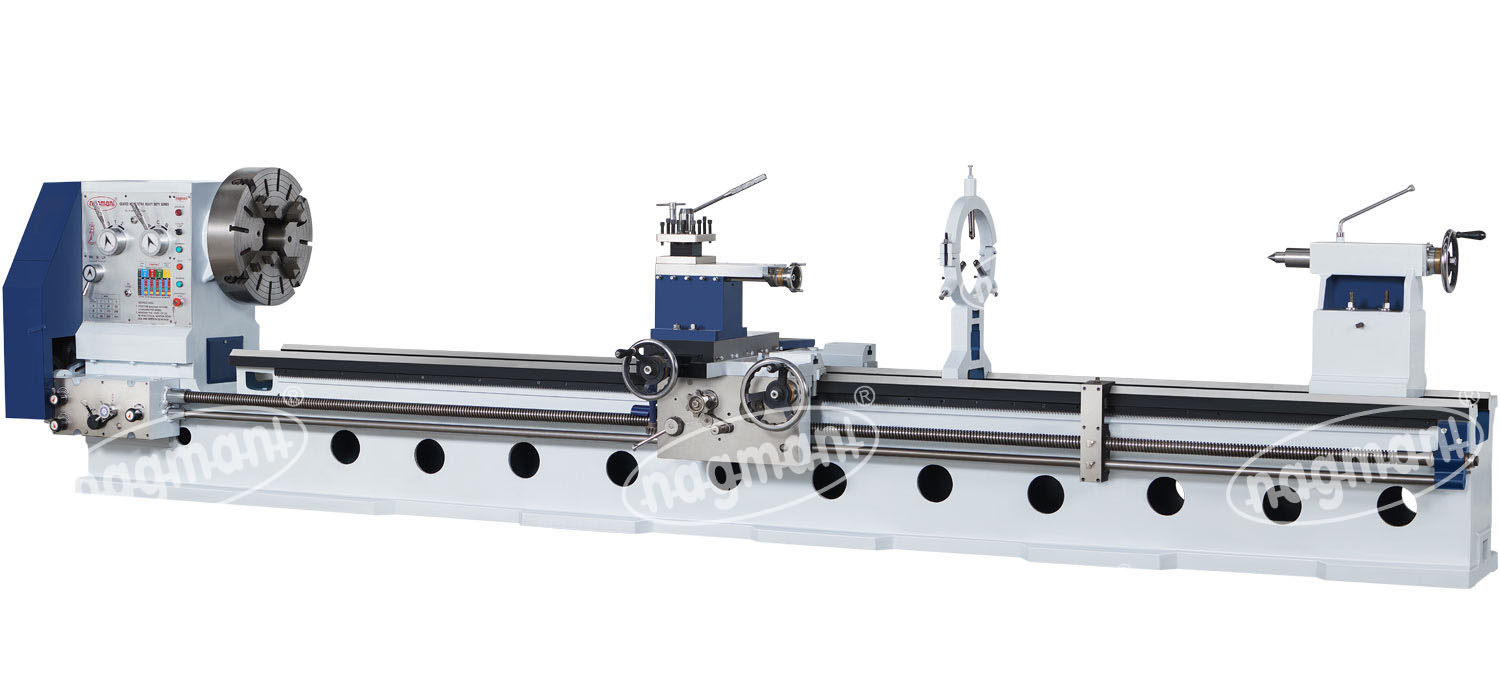

Extra Heavy Duty Geared Head Lathe Machine is specially Designed for the High RPM Upto 310. The Gears are equipped to obtain different speeds, which can be more than 9 Spindle speeds. This Machine is Widely used in Heavy Rubber Roll Mill, Extra Heavy Works, automobiles, power plants, aerospace, Etc

| Bed | EX HAG 558 | EX HAG 610 | EX HAG 660 | EX HAG 710 |

|---|---|---|---|---|

Flat & V Guide Way with Gap / Planner type Bed | ||||

| Width of Bed | 24"(610) | 26"(660) | 28"(710) | 30"(760) |

| Length of Gap | 6"(150) | 6"(150) | 6"(150) | 6"(150) |

| Length of Gap in Front of Fce Plate | 10"(250) | 10"(250) | 10"(250) | 10"(250) |

| Capacity | EX HAG 558 | EX HAG 610 | EX HAG 660 | EX HAG 710 |

|---|---|---|---|---|

| Height of Centre | 22"(558) | 24"(610) | 26"(660) | 28"(710) |

| Swing Over Bed | 41"(1040) | 45"(1145) | 50"(1270) | 53"(1350) |

| Swing Over Cross Slide | 30"(750) | 34"(850) | 38"(950) | 41"(1040) |

| Swing In Gap | 57"(1440) | 61"(1550) | 65"(1650) | 68"(1730) |

| Movement of Cross Slide | 22"(550) | 24"(600) | 26"(650) | 28"(700) |

| Movement of Compound Slide | 8"(200) | 8"(200) | 9"(230) | 9"(230) |

| Main Spidle | EX HAG 558 | EX HAG 610 | EX HAG 660 | EX HAG 710 |

|---|---|---|---|---|

| Type of Spindle | A2-11 type | A2-11 type | A2-11 type | A2-11 type |

| Spindle Bore | 125mm | 125mm | 125mm | 125mm |

| Spindle Morse Taper | MT-6 | MT-6 | MT-6 | MT-6 |

| Spindle Adapter Morse Taper | ||||

| No. of Speed / RPM Range | 8 / 14-200 RPM | 8 / 14-200 RPM | 8 / 14-200 RPM | 8 / 14-200 RPM |

| Tail Stock Spidle | EX HAG 558 | EX HAG 610 | EX HAG 660 | EX HAG 710 |

|---|---|---|---|---|

| Diameter | 88mm | 88mm | 88mm | 88mm |

| Morce Taper | MT-5 | MT-5 | MT-5 | MT-5 |

| Travel | 300mm | 300mm | 300mm | 300mm |

| Threads (For Fully Norton Gear Box.) | EX HAG 558 | EX HAG 610 | EX HAG 660 | EX HAG 710 |

|---|---|---|---|---|

| Metric Thread | (Total-24) / 0.5 to 15m.m | (Total-24) / 0.5 to 15m.m | (Total-24) / 0.5 to 15m.m | (Total-24) / 0.5 to 15m.m |

| Inch Thread | (Total-43) / 2 to 60 TPI | (Total-43) / 2 to 60 TPI | (Total-43) / 2 to 60 TPI | (Total-43) / 2 to 60 TPI |

| Lead Screw Dia | 50.8mm / 2TPI | 50.8mm / 2TPI | 50.8mm / 2TPI | 50.8mm / 2TPI |

| Electricals | EX HAG 558 | EX HAG 610 | EX HAG 660 | EX HAG 710 |

|---|---|---|---|---|

| Motor Power | 10 HP III Phase | 10 HP / 15 HP III Phase | 15 HP III Phase | 15 HP III Phase |

| Model EX.HAG 558 / 610 / 660 / 710 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length of Bed | 9'(2745) | 10'(3040) | 12'(3655) | 14'(4270) | 16'(4875) | 18'(5472) | 20'(6080) | 22'(6680) | 24'(7290) | 26'(7900) | 28'(8500) |

| Admin Between Centre | 900mm | 1200mm | 1800mm | 2400mm | 3000mm | 3600mm | 4200mm | 4800mm | 5400mm | 6000mm | 6600mm |

Note: As improvements are constantly made in our machines, the above illustrations, specifications, dimensions and technical data are subject to odification and changewithout prior notice and not binding on us. The descriptions of standard accessories confirms to it's list and not the photograph of the machine shown I the catalogue